We can provide comprehensive technical services for complete mash feed production line layout, process design, equipment manufacturing, installation, commissioning, electrical control and operation training, and technical formula for 10,000 to 1 million tons of livestock and poultry feed processing according to your specific demand.

Feed type adaptation:

Pellet feed: It needs to be equipped with a ring die pelletizer, countercurrent cooler and crushed particle grading equipment, suitable for concentrated feed processing.

Fermented feed: It needs to integrate microbial fermentation chamber, temperature control system and seamless conveying module.

High-fiber grass feed: It is equipped with a two-stage grinder and wear-resistant alloy steel ring die to avoid equipment wear.

Raw material characteristics adaptation:

Conventional raw materials such as corn/soybean meal: General water drop grinder can meet the requirements.

High-fiber raw materials such as straw: Two-stage grinding + variable frequency speed regulation motor is required to ensure that the fineness meets the standard.

Core equipment selection:

Grinding system: water drop grinder, equipped with pulse dust collector, general raw material grinding.

Two-stage grinder: Special for fiber raw materials, adjustable fineness, straw and forage processing.

Mixing system double-shaft paddle mixer: high mixing uniformity, support liquid addition, high-precision batching.

Pellet making system: ring die pellet machine (double discharge port), alloy steel ring die (wear-resistant) pellet feed production.

Fermentation module intelligent fermentation warehouse, fermentation completed in 48 hours for fermented feed.

Post-processing system countercurrent cooler automatic packaging machine: pellet temperature drops to room temperature, high packaging accuracy, pellet finished product processing.

Automation and intelligent configuration:

Control center

Adopt PLC central control system, integrated formula storage, production traceability, fault self-diagnosis function, support mobile phone remote monitoring.

Safety and environmental protection

Equipment linkage interlock overload protection, pulse dust collector dust recovery rate.

Energy-saving design

Frequency conversion motor reduces no-load energy consumption, waste heat recovery for raw material drying.

Plant layout and installation points:

Space planning

Linear layout of production line, reserved raw material yard and finished product warehouse.

Installation and commissioning

Suppliers are required to provide foundation map, equipment spacing is convenient for maintenance.

Compatibility design

Modular structure supports the later addition of puffing, expansion and other sections.

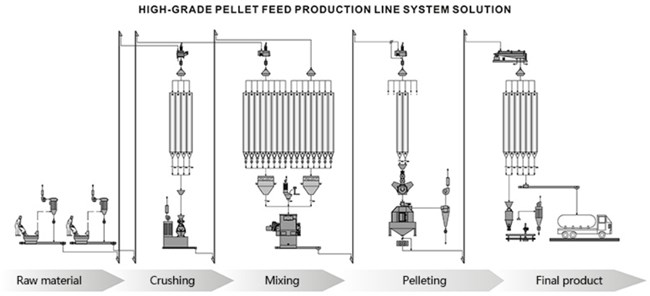

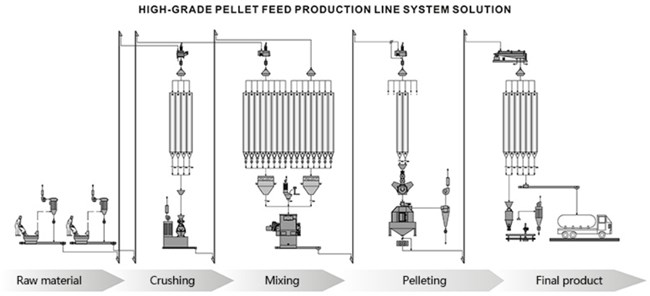

Our livestock poultry feed plant's sandard processing steps are as below:

1. Crushing Section

When the thickness of the raw material is >5 mm, the raw materials must be used for size reduction before the feedstock is sent to the Hammer Mill (crusher) to reach a diameter of less than 3 mm.

2. Mixing Section

Two-open doors structure, discharge rapidly, no leakage, no residue. Multiform liquid adding system and can be matched with compressed air jetting system. Suitable for mixing premix, poultry feed, aquatic feed, additives and chemical and medicine industries, etc.

3. Pelletizing Section

Acting as the heart part of the whole processing line, Ring Die Pellet Mill through adjusting the rotational speed of screw feeder axis to obtain the suitable flow of material, through the enforced feeder, enter the pressing room to pelletize finally.

4. Cooling Section

After the pelletizing process, the temperature of the feed pellet is about 60-80 degrees Celsius, with a moisture content of about 15%. A Cooler must then be used to reduce the moisture content of the wood pellets to about 3-4%, thereby making the feed pellets easier to store.

5. Classifying Screen

It is applicable for screening and classifying of mash or pellet feed. It is also can be used for cleaning of raw materials and classifyingof semi finished products after second grinding by large and medium feed mills.

6. Packing Section

After cooling and screening, the feed pellet must be protected from moisture and other environmental conditions. For this there is the packing process, which is effectively handled by our Semi-Auto Packing Machine.